Our Capabilities

Backed by cutting edge CNC and manual equipment, Farmers Machine provides quality in every part manufactured at our facility. Our machines do not break down meaning our customers know their parts will be delivered on-time every time. Simply because we rely on the highest level machines and PM with out compromise.

Turning capability:

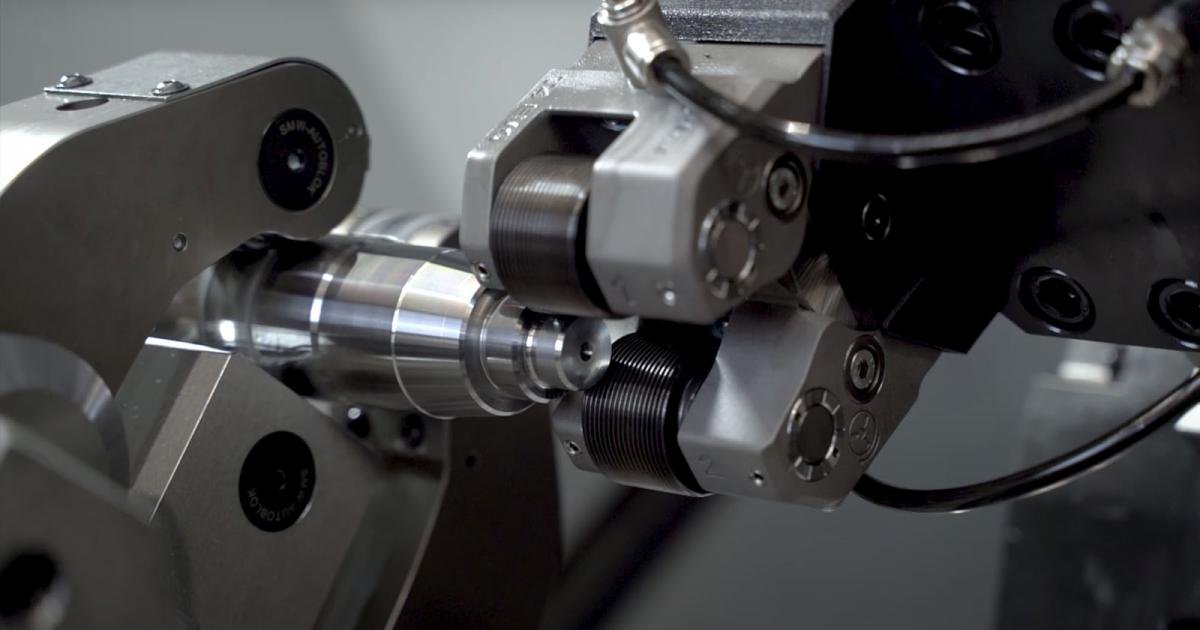

Doosan Lynx 220 LSYC Y-axis live tool 2014 model turning center.

Maximum turning diameter 11.8” x 20.1” long parts.

Collet chuck on A2-5 spindle nose.

24 position tool changer with dual station.

Through bore diameter 2.6”.

Swing over bed 23.6” over saddle 15.7”.

Fast feed rates at 1,181(X) 394(Y) and 1,417(Z)

Maximum main spindle 4,500 RPM, sub spindle 4,500 RPM, and live tool 6,000 RPM.

15/5/5 horsepower.

Y and C axis live tooling for complex geometries.

B-axis sub spindle with 5” three jaw chuck.

Barload automatic bar feeder for maximum 2.5” bars.

Ligths out unattended runs.

Achieves +-.0001” tolerance.

High production 1,000-100,000 part runs.

Spindle chiller guarantees no thermal expansion.

Axial and radial milling and drilling.

Automatic tool pre-setter for in process machining tool break detect and fast tool offset measurement for set ups.

High pressure coolant with TSC.

Parts catcher and parts conveyor.

Parts ejector on sub-spindle.

FANUC control.

External and internal broaching operations for keyways, squares, hexagons, serations, and custom forms.

Gear hobber operational.

Polygonal turning.

Deep drilling.

High precision bearing journals and bores.

Knurling.

Rigid tapping and single point ISO, UNC/UNF, and ACME threads.

Doosan Lynx 220 LMA live tool 2015 model turning center.

Maximum turning diameter 10” and 24” between centers.

A2-5 spindle nose.

24 position tool changer.

Through bore 2.5”.

Swing over bed 22.8” over saddle 15.2”.

Fast feed rates at 1,181(X) and 1,417(Z).

Maximum main spindle 4,500 RPM and live tool 6,000 RPM.

15/5 horsepower.

Live tooling with C-axis.

Achieves +-.0001” tolerance.

Prototype setup.

Bar puller set up for medium size production run.

Spindle chiller guarantees no thermal expansion.

Tailstock with live center for supporting long workpieces.

Eccentric turning configuration.

Axial and radial milling and drilling.

Tool pre-setter for fast tool offset measurement.

High pressure coolant with TSC.

Parts catcher.

6.5” hydraulic three-jaw chuck.

FANUC control.

External and internal broaching operations for keyways, squares, hexagons, serations, and custom forms.

Gear hobber operational.

Polygonal turning.

Sprocket manufacturing setup.

Deep drilling.

High precision bearing journals and bores.

Knurling.

Rigid tapping and single point ISO, UNC/UNF, and ACME threads.

Barload MTA International VSe-65 mm bar feeder.

Maximum outside diameter 2.5” and 70” long bars.

Lights out operation.

Automatic changeover.

Maximum 10 bars for 2.5” diameters and 25 bars for .250” diameters.

Spindle liners for anti-vibration.

Accepts tube, hexagonal, square, and round bars.

Milling capacity:

Sharp LMV Conventional milling machine.

Travels: 30”(X), 16” (Y), and 12”(Z).

3 axis with 6” three-jaw chuck rotary.

Kurt work holding 6” vise.

Prototype and repair work setup.

X and Y axis Sony DRO.

Welding and Fabrication capacity:

Lincoln electric 140 MPG welder.

MIG, TIG, stick, and stick welding.

Flexible location use with 110v input.

Gas shielded and flux-core wire.

Lincoln electric AC-225 arc welder.

Stick welding.

220v input.

Horizontal bandsaw.

Pedestal grinder.

Pedestal sander.

X-tool laser engraver.

20 ton hydraulic press.

10 ton arbor press.

Vevor tube/pipe bender.

Parts tumbler.

Parts washer.

Sand blasting and painting.